Net Zero 2045

Climate chA nge is the biggest challenge we face

net zero at Srm

Strategy

Performance

Capability

Resources

srm.com

Read more about

our role from our Sustainability Director Simon Richards here

of total UK GHG influenced by the built environment

(UKGBC, 2021)

42%

UK Emissions

Built Environment

Other

The buildings and infrastructure that form our built environment are a significant source of greenhouse gas emissions (GHG). Reducing these emissions and transitioning

to Net Zero poses a significant challenge.

The construction industry has a vital role to play in addressing the climate emergency.

We are placemakers and an industry of problem solvers who can harness our engineering excellence to deliver a built environment fit for our future.

There’s no silver bullet to this issue, and whilst our strategy is ambitious, it reflects the scale of the climate emergency that we all face and have a responsibility to address.

We will not be able to deliver this alone. Engagement and collaboration will be key. We all have a part to play.

Our Net Zero plan has been developed to ensure we take immediate and sustained action as we reach for our 2045 goal. Our aim is to make a positive impact on communities and the environment in which we operate, as we construct a better world for future generations.

OUR CHALLENGE

OUR CARBON PRINCIPLES

Don't Delay

Collaborate

Be Brave

Reduce

Transparency

Don't Delay

Collaborate

Be Brave

Reduce

Transparency

Don’t let the magnitude of the

challenge delay action

Work with the whole of Sir Robert McAlpine and the wider industry

We will have to do things differently and embrace change

Focus on reducing our emissions and long term benefit

We will be open, honest and

transparent always

OUR COMMITMENTS

Read more about the why the SBTi is important from our Company Carbon Manager, Simon Leek

The standard has enabled us to set ambitious and credible science-based Net Zero targets, aligned to our own carbon principles and with the Paris Agreement’s goal of keeping planetary warming to 1.5°C, thus limiting the worst impacts of climate change.

Crucially, our targets include all material sources of direct and indirect emissions, including those of our supply chain, and prioritise deep emission reductions of 90% by 2045. Before permanently neutralising residual emissions in line with SBTi criteria and reaching Net Zero.

We know reaching Net Zero will not be easy, but it’s increasingly clear that we no longer have the luxury of failure.

In the absence of policy and regulation, voluntary standards such as the SBTi’s Net-Zero standard are essential for providing a clear, consistent,

and science-based definition of Net Zero.

OUR TARGETS

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

tCO₂ e

4

3

2

1

Net Zero Emissions

Commence direct emissions (S1&2) offsetting

Neutralise residual value chain emissions

Offset direct (S1&2) emissions

1.5°C aligned emissions pathway

Target year emission reductions within value chain

Emission reductions within value chain

GHG EMISSIONS ACROSS THE VALUE CHAIN BY 2045

NET ZERO

Achieve long term target and neutralise residual emissions of full value chain through the permanent removal and storage of carbon from the atmosphere via the purchase of high quality,

certified removals

NEUTRALISE RESIDUAL VALUE CHAIN EMISSIONS:

During our transition to Net Zero take action to mitigate emissions beyond our value chain by purchasing high quality, certified credits equivalent to our direct scope 1&2 emissions

OFFSET OUR DIRECT SCOPE

1 & 2 EMISSIONS

Reduce absolute scope 1,2 & 3 GHG emissions from purchased goods and services by 90%

2045 LONG TERM TARGET:

Reduce absolute scope 1,2 & 3 GHG emissions from purchased goods and services by 42%

2030 NEAR TERM TARGET:

OUR NET ZERO

ALIGNED PATHWAY

Contact Us

Working for Us

About Us

+44 (0) 333 566 3444

information@srm.com

Sir Robert McAlpine Ltd

Eaton Court, Maylands Avenue

Hemel Hempstead

Hertfordshire

HP2 2TR

Current Vacancies

Working for us

Apprenticeships

Graduates

Student programmes

Modern Slavery

Projects

Our Services

Our Commitments

Our People & Culture

Accessibility

Privacy and Cookie Policy

Terms of Use

Sir Robert McAlpine 2023

Registered Office

To be renowned for our work with clients and communities as we construct a better world for future generations.

In order to realise that vision and continue proudly building Britain's future heritage, we want to help lead the transition to Net Zero and develop solutions that address this challenge.

Our vision

It won’t be easy. We know it can’t be achieved alone.

It’s why we developed our carbon principles to guide us

and underpin our Net Zero strategy.

In 2020 we made a commitment to become Net Zero by 2025 for our direct emissions. Halfway towards this milestone, we recognise this isn’t enough.

We will still offset our direct Scope 1 & 2 emissions by 2025; it’s the right thing to do. But claiming Net Zero or carbon neutral status only detracts from the work that still needs to be done. Net Zero must mean more.

It’s why we have become one of the first major construction and engineering companies in the UK to have had its targets approved as Net Zero by the Science Based Targets initiative (SBTi).

CLICK HERE TO SEE OUR SCIENCE BASED TARGETS IN FULL

Near-term Targets

Sir Robert McAlpine Ltd commits to reduce absolute scope 1 and 2 GHG emissions 42% by FY2030 from a FY2020 base year.* Sir Robert McAlpine Ltd also commits to reduce absolute scope 3 GHG emissions from purchased goods and services 42% within the same timeframe.

*The target boundary includes

land-related emissions and removals from bioenergy feedstocks.

Long-term Targets

Sir Robert McAlpine Ltd commits to reduce absolute scope 1 and 2 GHG emissions 90% by FY2045 from a FY2020 base year.* Sir Robert McAlpine Ltd also commits to reduce absolute scope 3 GHG emissions from purchased goods and services 90% within the same timeframe.

*The target boundary includes

land-related emissions and removals from bioenergy feedstocks.

Overall net

zero target

Sir Robert McAlpine commits to reach net zero greenhouse gas emissions across the value chain by FY2045 from a FY2020 base year.

of our emissions are Scope 3

98%

With transparency a key principle, our footprint has been calculated in line with the GHG protocol corporate value chain standard and independently verified and validated in accordance with ISO14064-1: 2018.

Our approach and methodology has also been reviewed by the SBTi and checked against its Net Zero standard, ensuring a robust, science-based approach has been adopted and that all material sources of emissions, including those of our supply chain, have been calculated as part of our footprint.

Given the significant impact our Scope 3 emissions have, bringing them within scope highlights this impact, and provides the impetus and opportunity to work collaboratively with our value chain to

target reductions.

Our performance

EMISSION REDUCTION INITIATIVES

Implementing initiatives to increase energy efficiency and reduce absolute carbon emissions.

COLLABORATION & INNOVATION

Supporting our clients and supply chain to achieve their own ambitions and drive innovation in low and zero carbon solutions.

OUR PEOPLE

Growing our expertise in delivering low and zero carbon solutions by engaging, training and empowering our people to make a difference.

PROCESS, SYSTEMS & DATA

Embedding carbon reduction into our decision making and ensuring the efficiency, accuracy and transparency of the data we collect.

All vehicles covered by our Sustainable travel policy to be ULEVs.

All company cars to be electric.

Review our commercial fleet and plant renewal plans.

Review energy strategies for all our non-leased offices and plant yards.

Develop and undertake energy efficiency drives.

Implement minimum carbon standards on all our projects.

Commit to the Climate Groups SteelZero and ConcreteZero initiatives.

Gain verification of our Net Zero Carbon targets by the SBTi.

rocure all elecricity on tariffs using 100% certified renewable energy.

Require the use of HVO fuel in all suitable plant and equipment.

2030

2027

2024

2023

ONGOING

Develop and roll out an in-use assessment for use by our clients on our projects.

Continue to grow our expertise in delivering Net Zero Carbon assets.

Collaborate with internal functions to fully transition to a NZC business.

Support industry initiatives to decarbonise and standardise our approach.

Implement a value chain engagement strategy to engender collaboration.

Share our knowledge, expertise and lessons learnt with our clients, peers and supply chain.

Invest, trial and upscale innovative low and zero carbon materials.

2025

ONGOING

Install EV charging across our non-leased offices and sites.

Develop an engagement campaign that challenges projects to reduce carbon.

Develop and undertake an employee commuter survey.

Embed carbon reduction requirements within all job roles and responsibilit-ies.

Continue the roll out of our carbon literacy programme to key disciplines.

Continue to support our multi-disciplinary Resource Efficiency Task Force.

Continue to support our multi-disciplinary Carbon Task Force .

Support remote working technology and flexible working.

Promote the use of SRMdrive, our ULEV car leasing scheme.

2025

2024

2023

ONGOING

Develop and implement a certified PAS2080 carbon management system.

Set embodied carbon benchmarks (kgCO2e/m2) on all projects.

Adopt our embodied carbon process on all projects.

Develop a carbon offsetting and removal strategy.

Embed carbon in our project governance process.

Step down our Net Zero targets to our sectors, monitor performance and set an internal price on carbon.

Implement our data improvement programme.

Maintain third party verification of our data.

2025

2024

2023

ONGOING

Our Net Zero action plan has been developed to ensure we take immediate and sustained action as we drive for

Net Zero greenhouse gas emissions across our value chain by 2045.

OUR ACTION PLAN

Total Scope 3 emissions

(tCO2e)

Reduction in absolute Scope 3 emissions

21%

2020

2023

2024

370,776

367,129

292,886

SCOPE 3 EMISSIONS

This has been driven by transitioning from a spend based approach to material specific quantities and emissions for key materials such as concrete and steel, and our efforts to procure low carbon concrete and steel, our 2 biggest carbon hotspots.

We've reduced our Scope 3 emissions by 21%. This is a result of improved accuracy in our purchased goods and services category.

reduction in absolute emissions

76%

Total Scope

1 and 2 emissions

market based (tCO2e)

2020

2024

6,305

6273

1,539

SCOPE 1 & 2 EMISSIONS

We've reduced our Scope 1 & 2 emissions by 76% since 2020.

This performance is driven by electrification of energy sources, the continued roll-out of renewable electricity tariffs and transition fuel, Hydrogenated Vegetable Oil (HVO), as a replacement for more

carbon-intensive diesel.

reduction in absolute Scope 1, 2 & 3

carbon emissions

22%

We’ve made good progress to date, having reduced total Scope 1, 2 & 3 emissions by 22% since 2020.

Scroll down for a detailed breakdown of our Scope 1,2 & 3 emissions performance.

Total Scope

1, 2, and 3 emissions

market based (tCO2e)

2020

2024

377,080

294,425

Target 1.5 aligned emission pathway

Total scope 1,2 & 3 emissions - market based (t CO2e)

SCOPE 1, 2 & 3

CARBON EMISSIONS

Scope 1 & 2 Breakdown

2020

4%

Other

20%

Electricity

Market

Based

23%

Gas

52%

Diesel

Scope 1 & 2 Breakdown

2024

15%

Other

18%

Gas

24%

Electricity

Market Based

42%

Diesel

Scope 3 Breakdown

2020

2%

Other

11%

Other

89%

Purchased goods

& services

Scope 3 Breakdown

2024

4%

Purchased goods

& services

(non-product)

12%

Other

88%

Purchased goods

& services

CLICK HERE TO SEE OUR SCIENCE BASED TARGETS IN FULL

CLICK HERE TO SEE FULL BREAKDOWN

Other (Kerosene, HVO, F-Gas, Company Car)

CLICK HERE TO SEE FULL BREAKDOWN

Other (capital goods, fuel and energy related activities, upstream transport and distribution, waste, business travel, employee commuting, investments)

ICE carbon champion at Oxford

click to find out more

Click to find out more about Gradels

A platform approach & Net Zero at The Forge

click to find out more

Click to find out more about The Forge

Innovative low carbon concrete at 1 Broadgate

click to find out more

Click to find out more about low carbon concrete

Design Group deliver low carbon solutions click to find out more

Click to find out more about MDG/Healthcare

Designing out carbon at 1 Centenary Way

click to find out more

Click to find out more about

1 Centenary way

Net Zero at 100 Liverpool Street

click to find out more

Click to find out more about 100 Liverpool Street

Transition to low carbon fuel

click to find out more

Click to find out more about HVO fuel

Life Cycle Assessment at Edinburgh Park

click to find out more

Click to find out more about Edinburgh Park

Saved 203 tCO2e through alternative timber roof design

Saved 100 tCO2e by using UK Ancaster limestone

A feasibility study to explore alternative construction methodologies and coverings for the main roof reduced embodied carbon by 203 tCO2e by switching to a glue laminated timber structure with tessalted aluminium tiles. Other carbon reduction measures included: replacing cement in the piled foundations and substructure with ground granulated blast slag (GGBS) - saving 433 tCO2e and UK Ancaster limestone for cladding - saving 100 tCO2e. During construction the project also utilised a 100% renewable energy backed tariff and encouraged staff to use park and ride services.

The successful carbon-saving initiatives at Gradel College, Oxford earned the project ICE Carbon Champion status.

ICE Carbon Champion status at Oxford

8% less steel and 13% less concrete compared to baseline

Fully electric, EPC 'A' and NABERS 5-star rated building

The approach maximises the efficiency of materials and minimises waste, with externally validated claims showing 8% less steel and 13% less concrete compared with a business-as-usual baseline. The Forge is also the first commercial building to be both constructed and operated in line with the UKGBC’s ‘Net Zero Carbon’ buildings framework. The building delivered a 38% embodied carbon (A1-A5) saving, initiatives included: optimised concrete mix designs and post consumer reclaimed raised access floor utlised in lieu of new – saving 497 (A1-A3) tCO2e. The building is fully electric, achieving an 'A' EPC rating and is expected to achieve a 5-star NABERS UK rating once fully operational.

The Forge is the world's first major commercial building to be designed and built using the platform approach to Design for Manufacture and Assembly (P-DfMA).

Platform approach & Net Zero Carbon at The Forge

20% reduction in embodied carbon (A1-A3) through the use of AACMs

43% reduction in the average carbon intensity of concrete mixes

Working with our supply chain, we developed this further in a later phase of piling to specify EcoPact Max concrete, an innovative cement alternative technology from Aggregate Industries that utilises alkali activated cementitious materials (AACMs) and high levels of GGBS (95%) to remove the need for any cement at all. This resulted in a 20% reduction in embodied carbon (A1-A3) compared to a typical mix, saving 356 tCO2e.

At 1 Broadgate, we increased the amount of Ground Granulated Blast Furnace Slag (GGBS) content in the hard and soft piles to 70% and 95% respectively, with the soft pile mix a specially developed low carbon solution containing less than 12.5 kg cement per m³ of concrete.

Innovative low carbon concrete

77% reduction in embodied carbon (A1-A3) at Kingsway & Chesterfield hospitals

54% reduction in embodied carbon (A1-A3) at the National Rehabiliation Center

A prime example is our work on three healthcare schemes at Kingsway Hospital, Chesterfield Hospital and the National Rehabilitation Centre. At Kingsway and Chesterfield Hospitals, MDG’s alternative foundation designs reduced embodied carbon by up to 77%, saving over 1,000 tCO2e on each project. At the National Rehabilitation centre, embodied carbon was reduced by 54%, saving 538 tCO2e.

Our in-house design experts, McAlpine Design Group (MDG), embody our desire and capability to deliver low carbon solutions for our clients.

Design Group deliver low carbon solutions

64% steel frame recycled content

40% reduction in embodied carbon (A1-A3)

We worked with our supply chain partners to identify and install a steel frame solution which delivered a significant reduction in embodied carbon and had the added benefit of increasing the head height clearance on each floor. Our alternative solution increased the recycled content of the steel to 64%. Embodied carbon emissions decreased by 40%, 36% and 10% for the Whole Life Carbon Assessment stages A1 to A3, A1 to A5 and A to D, respectively.

By applying our expertise to scrutinise the design of our One Centenary Way project in Birmingham, we were able to deliver significant carbon reductions.

Designing out carbon at One Centenary Way

32% of existing frame reused (3,435 tCO2e saving)

49% of existing foundations & slabs reused (4086 tCO2e saving)

Carbon reduction was a primary driver, and from the outset of the design concept, the team looked to retain and reuse as much of the existing building as possible. This was coupled with design solutions focused on reducing the embodied carbon of the major building packages, like concrete and steel. The combination of these measures dramatically reduced the environmental impact of the building, which has gone on to win multiple industry accolades.

100 Liverpool Street was our client British Land’s first Net Zero Carbon development. Buy-in from everyone involved in the project helped our team deliver exceptional results.

Delivering British Land’s first Net Zero Carbon project

1 million litres of HVO fuel used to date.

2,500 tCO2e saved

We've used more than 1 million litres of HVO fuel on our projects, saving 2,500 tCO2e. And we've transitioned more than 50% of our vehicle fleet to run on HVO, with plans in place to increase this to around 80% by the end of 2023. On our A19 Highway Maintenance project we've saved 175 tCO2e alone by identifying plant and vehicles which could switch to HVO from diesel.

With alternative fuels such as Hydrogenated Vegetable Oil (HVO), reducing CO2 emissions by up to 90%, we're using them as a key transition fuel on our decarbonisation journey.

Transition to low carbon fuels

Over 1,000 tCO2e saved

Reuse of materials, optimised

concrete mixes & low carbon aluminium

The report detailed our methodology and inputs, along with the carbon savings realised and carbon emissions associated with the project at practical completion (upfront carbon – A1-A5) and end of life (life cycle embodied carbon - A1-A5, B1-B5 & C1-C4). We also captured lessons learnt from the process to improve the efficiency and accuracy of assessments on future projects. Supported by our reporting procedures, tools, and supply chain relationships, we ensured the assessment included: quantity and type of material/product delivered and intalled including project specific Environmental Product Declarations (EPD), transport distances for materials and products, fuel, electricity and water consumption and waste generated during construction.

At Edinburgh Park, we used our in-house capability to undertake an as-built Life Cycle Assessment (LCA) of the carbon emissions for our client at completion.

As-built life cycle assessment at Edinburgh Park

CASE STUDIES

Scope 1 emissions: direct emissions from sources owned or directly controlled by the organisation e.g., use of fuel in SRM plant

Scope 2 emissions: indirect emissions from purchased energy e.g., electricity we use

Scope 3 emissions: indirect emissions that are a consequence of our activities but arise from sources that are not owned or directly controlled by us e.g. embodied carbon of materials.

Science based pathway / target: trajectory/target to achieve global Net Zero emissions based on scientific evidence.

1.5°c aligned pathway: emissions are reduced in line with a 1.5°c warming scenario/budget. The scientific consensus is that we must limit global warming to 1.5°c or below to limit the worst impacts of climate change.

Net Zero: Permanently neutralising any residual emissions at the net-zero target year and any emissions released into the atmosphere thereafter. Residual emissions can not exceed 10% of baseline year emissions.

Residual emissions: emissions that remain after taking all possible actions to implement emissions reductions.

Carbon removal: permanent withdrawal and storage of carbon from the atmosphere as a result of deliberate human activities.

Carbon offset: emissions reduction or removal resulting from an action outside the organisations boundary used to counterbalance the organisations residual emissions.

Greenhouse gases: Greenhouse gases (GHGs) such as Carbon dioxide (CO2), methane (CH4) and nitrous oxide (N2O) are gases in the earth's atmosphere that trap heat.

Life cycle assessment: A procedure to quantify carbon emissions (embodied and operational) and other environmental impacts (such as acidification and eutrophication) through the life stages of a building. The EN 15978 standard is typically used to define the different life cycle stages.

Embodied carbon: The carbon emissions associated with the extraction and processing of materials, the energy and water consumption used by the factory in producing the products, transporting materials to site, and constructing the building. As well as the carbon emissions associated with the ‘in-use’ stage (maintenance, replacement, and emissions associated with refrigerant leakage) and ‘end of life’ stage (demolition, disassembly, and disposal) of the building over its lifecycle.

Carbon Reduction Plan

(PPN 06/21)

Pathway to Net Zero

Tags

Sustainability at SRM

reduction in Scope

1 & 2 emissions

60%

1/1

2020

Signed supply agreement for HVO fuel and began rolling out to our projects

2/2

Committed to

the Science Based

Targets initiative

(SBTi) business

ambition for 1.5°c

1/2

2021

22%

reduction in Scope

1, 2 & 3 emissions

4/4

86%

of electricity supplied

by a 100% renewable energy tariff

3/4

Submitted

our emission reduction targets

to the SBTi for validation

2/4

Launched our

electric vehicle

car scheme

1st diesel-free site

1/4

2022

Net Zero targets

validated by

the SBTi

2/2

Committed to the

climate groups

SteelZero and

ConcreteZero

initiatives

1/2

2023

Energy efficiency

drives undertaken

3/3

Minimum carbon

standards including

low carbon site set

up implemented on

all our projects

2/3

Publish our

offsetting strategy

1/3

2024

100%

of Scope 1 & 2 emissions will be offset

5/5

30%

of concrete we specify and procure will meet the ConcreteZero low embodied carbon concrete threshold

4/5

All fuel used in

our plant and equipment to be HVO

3/5

All electricity to be procured on REGO backed renewable energy tariffs

2/5

Embodied carbon benchmarks set and

monitored against

on all our projects

1/5

2025

42%

reduction in absolute Scope

1, 2 and 3 GHG emissions from purchased goods and services

5/5

50%

of the steel we specify

or procure will be from manufacturers who are responsible steel certified or from a site with science based targets our

4/5

of the concrete we specify

or procure will meet the ConcreteZero low embodied carbon concrete threshold

50%

3/5

of company cars to be

an electric vehicle

100%

2/5

of vehicles covered by our sustainable travel policy to be an Ultra low Emission Vehicle (ULEV)

100%

1/5

2030

All residual

emissions offset through certified removal schemes

4/5

reduction in absolute

Scope 1, 2 and 3 GHG

emissions from purchased goods and services

90%

3/5

of the steel we specify

or procure will be

Net Zero

100%

949 3811 9761

2/5

of the concrete we specify

or procure will be net zero

100%

1/5

2045

2020

2021

2022

2023

2024

2025

2030

2045

MILESTONES ACHIEVED

TARGET MILESTONES

OUR PATHWAY TO NET ZERO

Low carbon site establishment

Low carbon plant

& equipment

Plant

Whole market solutions

Strategic framework suppliers

Market testing

Full supply chain traceability

Procurement &

supply chain

Efficient

temporary works

Low carbon structures

Concrete innovation

Passivhaus

Design Group

Whole Life Carbon solutions

Optimized environmental strategies

Soft landings – operated as designed

Building

Services

Low carbon design and systems

Whole Life Carbon solutions

Key supply chain relationships

Facades

Life Cycle Assessments

As built embodied carbon data

low carbon lead, advice & support

PAS2080 aligned

carbon management

Sustainability

Plant

Procurement & Supply Chain

Design Group

Building Services

Facades

Sustainability

Our integrated centres for excellence deliver low carbon solutions for our clients and projects at all stages of the project lifecycle:

Our capability

Accessibility Tool

Performance

Strategy

Capability

Resources

2020

2021

2022

2023

2024

2025

2030

2045

Sustainability

Sustainability

Facades

Facades

Building Services

Building Services

Design Group

Plant

Plant

Procurement & Supply Chain

Procurement & Supply Chain

Resources

Key Definitions

Year

Resources

Carbon Reduction Plan

(PPN 06/21)

Pathway to Net Zero

Key Definitions

Key Definitions

Scope 1 emissions: direct emissions from sources owned or directly controlled by the organisation e.g., use of fuel in SRM plant

Scope 2 emissions: indirect emissions from purchased energy e.g., electricity we use

Scope 3 emissions: indirect emissions that are a consequence of our activities but arise from sources that are not owned or directly controlled by us e.g. embodied carbon of materials.

Science based pathway / target: trajectory/target to achieve global Net Zero emissions based on scientific evidence.

1.5°c aligned pathway: emissions are reduced in line with a 1.5°c warming scenario/budget. The scientific consensus is that we must limit global warming to 1.5°c or below to limit the worst impacts of climate change.

Net Zero: Permanently neutralising any residual emissions at the net-zero target year and any emissions released into the atmosphere thereafter. Residual emissions can not exceed 10% of baseline year emissions.

Residual emissions: emissions that remain after taking all possible actions to implement emissions reductions.

Carbon removal: permanent withdrawal and storage of carbon from the atmosphere as a result of deliberate human activities.

Carbon offset: emissions reduction or removal resulting from an action outside the organisations boundary used to counterbalance the organisations residual emissions.

Greenhouse gases: Greenhouse gases (GHGs) such as Carbon dioxide (CO2), methane (CH4) and nitrous oxide (N2O) are gases in the earth's atmosphere that trap heat.

Life cycle assessment: A procedure to quantify carbon emissions (embodied and operational) and other environmental impacts (such as acidification and eutrophication) through the life stages of a building. The EN 15978 standard is typically used to define the different life cycle stages.

Embodied carbon: The carbon emissions associated with the extraction and processing of materials, the energy and water consumption used by the factory in producing the products, transporting materials to site, and constructing the building. As well as the carbon emissions associated with the ‘in-use’ stage (maintenance, replacement, and emissions associated with refrigerant leakage) and ‘end of life’ stage (demolition, disassembly, and disposal) of the building over its lifecycle.

Climate change is the biggest challenge we face

Discover how we are addressing it

TOP

EMISSION REDUCTION INITIATIVES

Implementing initiatives to increase energy efficiency and reduce absolute carbon emissions.

COLLABORATION & INNOVATION

Supporting our clients and supply chain to achieve their own ambitions and drive innovation in low and zero carbon solutions.

OUR PEOPLE

Growing our expertise in delivering low and zero carbon solutions by engaging, training and empowering our people to make a difference.

PROCESS, SYSTEMS & DATA

Embedding carbon reduction into our decision making and ensuring the efficiency, accuracy and transparency of the data we collect.

All vehicles covered by our Sustainable travel policy to be ULEVs.

2030

All company cars to be electric.

2027

Review our commercial fleet and plant renewal plans.

Review energy strategies for all our non-leased offices and plant yards.

Develop and undertake energy efficiency drives.

Implement minimum carbon standards on all our projects.

2024

Commit to the Climate Groups SteelZero and ConcreteZero initiatives.

Gain verification of our Net Zero Carbon targets by the SBTi.

2023

Procure all elecricity on tariffs using 100% certified renewable energy.

Require the use of HVO fuel in all suitable plant and equipment.

ONGOING

Develop and roll out an in-use assessment for use by our clients on our projects.

2025

Continue to grow our expertise in delivering Net Zero Carbon assets.

Collaborate with internal functions to fully transition to a NZC business.Support industry initiatives to decarbonise and standardise our approach.

Support industry initiatives to decarbonise and standardise our approach.

Implement a value chain engagement strategy to engender collaboration.

Share our knowledge, expertise and lessons learnt with our clients, peers and supply chain.

Invest, trial and upscale innovative low and zero carbon materials.

ONGOING

Install EV charging across our non-leased offices and sites.

2025

Develop an engagement campaign that challenges projects to reduce carbon.

2024

Develop and undertake an employee commuter survey.

Embed carbon reduction requirements within all job roles and responsibilit-ies.

Continue the roll out of our carbon literacy programme to key disciplines.

2023

Continue to support our multi-disciplinary Carbon Task Force .

Continue to support our multi-disciplinary Carbon Task Force .

Support remote working technology and flexible working.

Promote the use of SRMdrive, our ULEV car leasing scheme.

ONGOING

Develop and implement a certified PAS2080 carbon management system.

Set embodied carbon benchmarks (kgCO2e/m2) on all projects.

Adopt our embodied carbon process on all projects.

2025

Develop a carbon offsetting and removal strategy.

2024

Embed carbon in our project governance process.

2023

Step down our Net Zero targets to our sectors, monitor performance and set an internal price on carbon.

Implement our data improvement programme.

Maintain third party verification of our data.

ONGOING

Our Net Zero action plan has been developed to ensure we take immediate and sustained action as we drive for Net Zero greenhouse gas emissions across our value chain by 2045.

OUR ACTION PLAN

Accessibility Tool

Go to srm.com

368,843

2023

1,714

2023

Scope 1 & 2 Breakdown

2023

15%

Other

24%

Gas

17%

Electricity

Market Based

45%

Diesel

Scope 1 & 2 Breakdown

2023

Other

24%

Gas

17%

Electricity

Market Based

45%

Diesel

15%

Scope 3 Breakdown

2023

16%

Other

84%

Purchased goods

& services

Scope 3 Breakdown

2023

16%

Other

84%

Purchased goods & services (product)

368,843

2023

1,714

2023

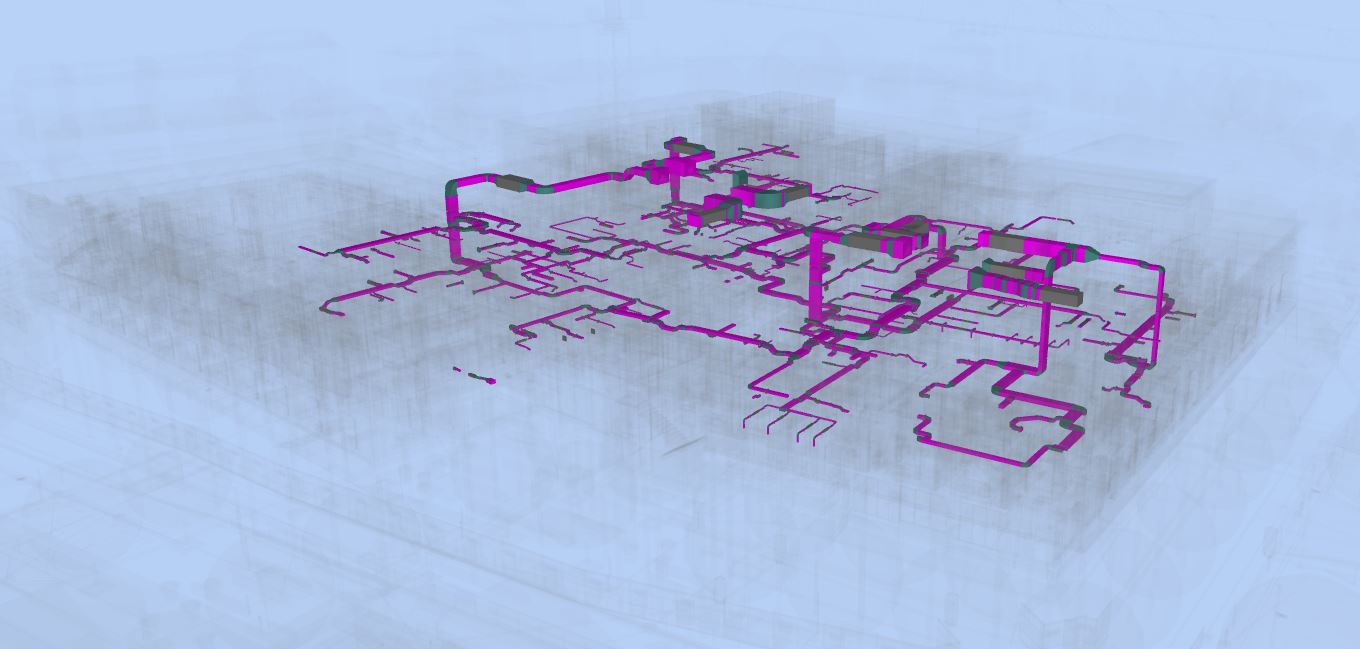

SRM has been partnered with digital solutions provider Dalux since 2018, and since its release in Q3 2023, SRM has been rolling out the Dalux ‘Quantities’ function on all projects. This tool enables streamlined 3D model-based quantification and estimation of construction materials.

Project-based staff can now easily extract quantity information from live designs to inform embodied carbon analysis, target setting, and the embedment of carbon in our decision-making process. The tool is helping us deliver lower carbon outcomes and with greater certainty of the results.

An essential part of embodied carbon assessments and optioneering is having access to up-to-date and precise material quantity information.

Company-wide implementation of Dalux ‘Quantities’

We've used more than 1.9 million litres of HVO fuel on our projects to date, saving over 5,000 tCO2e. We acknowledge the challenges and risks associated with the use of HVO, and have worked hard to ensure the provenance of our supply meets our ethical and responsible sourcing requirements.

With alternative fuels such as Hydrotreated Vegetable Oil (HVO), reducing CO2 emissions by up to 90%, we're using them as a key transition fuel on our decarbonisation journey.

Transition to low carbon fuels

1.9 million litres of HVO fuel used to date

5,000 tCO2e saved

The HPU from GeoPura uses green hydrogen to generate zero-emission electricity, offering a sustainable plug and play alternative to diesel generators. With only water and heat as by-products. The week-long trial generated nearly 6,000 kWh, saving 8 tCO2e, 56kg NOx and 2 kg Particulate Matter, compared to a diesel equivalent. Noise levels were also reduced, due to quieter operation of the HPU.

Overall, the trial proved hydrogen technology as a safe and viable alternative for projects that lack access to a permanent electricity supply but are looking to achieve zero-emission site power.

Our plant department in Kettering has been trialling the use of a cutting-edge Hydrogen Power Unit (HPU) to deliver Net Zero power.

Green Hydrogen trial

Material passports are digital documents detailing a building’s components, characteristics, and materials. They provide vital information that helps track the materials used during construction, such as specific concrete mixes, façade components, and steelwork origins. This data supports the reuse and repurposing of materials, promoting a circular economy and reducing waste and carbon emissions.

The project received an innovation credit under BREEAM for this initiative – utilised as part of the project strategy for BREEAM Outstanding. The initiative also won the ‘Delivering Sustainability with Digital Innovation’ accolade at the 2024 Digital Construction Awards.

1 Broadgate stands out as the first large-scale project to implement a digital-led material passport process.

Material Passports at 1 Broadgate

Our Three Chamberlain Square project in central Birmingham has demonstrated this by utilising a lean post-tensioned concrete structural frame and an innovative off-site prefabrication approach to the drylining works. Reducing material use, waste and emissions.

By reducing material use and reducing waste, the project is currently on track to achieve an embodied carbon result of just 479 kgCO2e/m2 (A1-A5), an exceptionally low figure for an entirely new building, along with BREEAM Outstanding and NABERS 5* accreditations.

Using less material as an industry is fundamental to reducing emissions.

Material efficiency at 3 Chamberlain Square

The approach maximises the efficiency of materials and minimises waste, with an estimated 18% less steel and 13% less concrete compared to a traditional solution. The development won the Innovation award at the 2024 BCO (British Council for Offices) Awards.

The Forge is also the first commercial building to be both constructed and operated in line with the UKGBC’s ‘Net Zero Carbon’ buildings framework. The building delivered an estimated 38% embodied carbon (A1-A5) saving compared to the project’s Stage 3 ‘BAU’ baseline. The building is also fully electric, achieving an 'A' EPC rating and is expected to achieve a 5-star NABERS UK rating once fully operational.

The Forge is the world's first major commercial building to be designed and built using the platform approach to Design for Manufacture and Assembly (P-DfMA).

Platform approach & Net Zero Carbon at The Forge

At our 100 Liverpool Street project, we retained approximately one third of the pre-existing structural steel frame. At 1 Broadgate, we sensitively dissembled 140 tonnes of structural steelwork from the existing asset to be re-used in another London development. Lastly, at 2 Finsbury Avenue, we identified 98 structural steel beams that could be disassembled from the existing asset and reused within the newly constructed development – saving approximately 43 tonnes of CO2e (A1-A3).

At our Broadgate framework with British Land, we have minimised our demand for new steelwork through engineering excellence.

Retained and Reclaimed Steel

Basalt comparatively reduces carbon emissions by ~60% (A1-A3) compared to steel. It is also significantly lighter and requires no hot works, improving health and safety on our sites.

We have been utilising basalt reinforcement in lieu of steel within our projects temporary works This includes basalt reinforced temporary guide walls at 2 Finsbury Avenue and temporary foundation pads at our Align JV at HS2.

Basalt Fibre Reinforcement

At a project in central London, we have been utilising a 100% Portland cement free mortar for internal masonry blockwork walls. The ‘Cemfree’ mortar provides embodied carbon savings of around ~70% (A1-A3) compared to industry leading Portland cement-based mortars. The mortar is also considered easier to clean off and remove, therefore a greater potential for blockwork to be reused when the walls are eventually demolished.

At a project in central London, we have been utilising a 100% Portland cement free mortar for internal masonry blockwork walls.

Cement Free Masonry Mortar

At our National Gallery 200 Welcome Project, we successfully coordinated the careful removal of pre-existing architectural grade glass and returned it a UK glass manufacturer for recycling into new glazing products, helping reduce emissions in the factory.

One of the barriers to lower carbon glazing products is the lack of high-quality post-consumer cullet returning to production facilities.

Glazing Recycling at The National Gallery

A newly BS 8500:2023 compliant ternary blend cement (CVI-SL) was introduced for self-compacting concrete and visual concrete mixes. This reduced the Portland cement content, whilst also reducing reliance on GGBS as a cement replacement, by incorporating limestone filler as a ternary blend. The change helped reduce embodied carbon on the project whilst improving the availability of GGBS in the market.

The Museum of London team collaborated with the supply chain to reduce the embodied carbon of concrete used on site, whilst also reducing reliance on GGBS in accordance with the latest low carbon industry guidance.

Ternary Blend Cement at The Museum of London

The new low carbon concrete has a carbon footprint following industry BSI PAS2050 calculation rules that gives a 62% reduction in CO2e per cubic metre of concrete, compared to a standard CEMI concrete, meeting the same specification in the same raw materials. The mixes trialled used up to 90% supplementary cementitious material (SCM) with an alkali activated cementitious material conforming to BS EN197.

At HS2’s Align consortium – a joint venture between Sir Robert McAlpine, Bouygues Travaux Publics, and VolkerFitzpatrick – we trialled the use of an ultra-low-carbon concrete with manufacturer Tarmac for the floor slab and parts of the walls for a pre-cast factory.

Align trial innovative low carbon concrete

The materials we exchange through the platform are assigned a digital resources passport, providing a comprehensive material identity which can be tracked and traced through the supply chain – ensuring accountability and transparency. The platform helps our projects increase the number of reclaimed materials used in our works and maximise the reuse of waste generated on our sites.

We recognise the importance of the circular economy in mitigating climate change. All our projects have access to the Excess Materials Exchange (EME) platform, this digital matching platform connects companies in the construction sector, enabling them to identify, exchange, and repurpose excess materials transforming potential waste into valuable resources.

Excess Materials Exchange

The typical nature of power consumption on construction sites means peaks and troughs are common. However, this also means generators are often oversized due to the misconception of incorporating greater power to meet start-up demand. By understanding the load profile and any patterns or timings, we can optimise the use of BESS, and integrate the best generator and BESS combination to reduce fuel costs and emissions.

We partnered with specialist Aggreko to analyse five live tower cranes for emissions and fuel savings utilising smaller generators, BESS, and more sustainable fuels. Our projects achieved an 85% reduction in emissions across the five tower cranes with Aggreko’s BESS after rightsizing generators. That is equivalent to more than 234 tonnes of CO2 and 87,300 litres of fuel saved.

Battery Energy Storage Systems (BESS)

Our PAS 2080 accredited carbon management system rewards our sites for utilising electric machinery instead of plant with internal combustion engines. This can reduce carbon emissions whilst also creating a healthier work environment for site operatives and reducing nuisance to our local communities.

An example being our Barkers of Kensington site in central London, through consultation our supply chain used a plethora of electric machinery such as electric telehandlers, electric mini-excavators, electric wheel dumpers, electric mini-dumpers and a number of electric robotic breakers.

Electric Site Machinery at Barkers of Kensington

The engineers at MDG found that the proposed solution could be significantly refined saving cost, time and materials, plus the associated embodied carbon reduced through the saved materials. The MDG optimised design reduced steel usage by over 18 tonnes and eliminated 150 metres of associated welding – this intervention saved a comparative 41tCO2e (A5).

The McAlpine Design Group (MDG) were employed by The Westbury Hotel project team to check the efficiency and efficacy of an earth retention proposal.

Optimised Temporary Works at The Westbury Hotel

This was achieved through a focus on passive measures, such as cooling exposed concrete soffits as thermal mass and fresh air ventilation. The building is all-electric with renewable power generated partly via a rooftop PV array. We also used our in-house capability to undertake an as-built embodied carbon assessment for our client at completion. This aided the carbon quantification of the structurally efficient concrete frame, lean finishes and optimised concrete mix designs – helping capture achievements and aid lessons learned.

Our multi-award winning 1 New Park Square office building in Edinburgh achieved one of the best office energy performance certificates recorded in Scotland – with an EPC of ‘A -03’.

Low Carbon Performance at 1 New Park Square (supersede Edinburgh Park)

Select the circles below to read the case studies.

CASE STUDIES

TOP

Company-wide implementation of Dalux ‘Quantities’

Transition to low carbon fuels

Green Hydrogen

Trial

Material Passports at 1 Broadgate

Material efficiency at

3 Chamberlain Square

Platform approach & Net Zero Carbon at The Forge

Retained and Reclaimed Steel

Basalt Fibre Reinforcement

Cement Free Masonry Mortar

Glazing Recycling at The National Gallery

Ternary Blend Cement at The Museum of London

Align trial innovative low carbon concrete

Excess Materials Exchange

Battery Energy Storage Systems (BESS)

Electric Site Machinery at Barkers of Kensington

Optimised Temporary Works at The Westbury Hotel

We’ve become one of the first Tier 1 contractors to meet the PAS 2080:2023 standard for both our buildings and infrastructure divisions. This certification demonstrates that we have the systems, processes and capability to manage net-zero aligned performance on our projects throughout their lifecycles.

Our carbon management system

Sir Robert McAlpine have delivered an exceptional carbon management system which has secured the verification of PAS 2080:2023. This is a real achievement, supporting carbon reduction across their built environment portfolio of projects.

Matthew Pygott

Lead Verifier, Hydrock Ltd

Our carbon management system has several benefits for projects, including:

Ensuring carbon implications are considered alongside cost, programme and quality when project decisions are made – drawing on robust data and relevant experience

Creating a framework for collaboration within project teams and the wider value chain – eliciting effective ideas at the right time and making sure everyone understands their responsibilities

Giving clients confidence in the delivery of net-zero aligned carbon targets and the associated sustainability accreditations desired

SRM has been partnered with digital solutions provider Dalux since 2018, and since its release in Q3 2023, SRM has been rolling out the Dalux ‘Quantities’ function on all projects. This tool enables streamlined 3D model-based quantification and estimation of construction materials.

Project-based staff can now easily extract quantity information from live designs to inform embodied carbon analysis, target setting, and the embedment of carbon in our decision-making process. The tool is helping us deliver lower carbon outcomes and with greater certainty of the results.

An essential part of embodied carbon assessments and optioneering is having access to up-to-date and precise material quantity information.

Company-wide implementation of Dalux ‘Quantities’

We've used more than 1.9 million litres of HVO fuel on our projects to date, saving over 5,000 tCO2e. We acknowledge the challenges and risks associated with the use of HVO, and have worked hard to ensure the provenance of our supply meets our ethical and responsible sourcing requirements.

With alternative fuels such as Hydrotreated Vegetable Oil (HVO), reducing CO2 emissions by up to 90%, we're using them as a key transition fuel on our decarbonisation journey.

Transition to low carbon fuels

5,000 tCO2e saved

1.9 million litres of HVO fuel used to date

The HPU from GeoPura uses green hydrogen to generate zero-emission electricity, offering a sustainable plug and play alternative to diesel generators. With only water and heat as by-products. The week-long trial generated nearly 6,000 kWh, saving 8 tCO2e, 56kg NOx and 2 kg Particulate Matter, compared to a diesel equivalent. Noise levels were also reduced, due to quieter operation of the HPU.

Overall, the trial proved hydrogen technology as a safe and viable alternative for projects that lack access to a permanent electricity supply but are looking to achieve zero-emission site power.

Our plant department in Kettering has been trialling the use of a cutting-edge Hydrogen Power Unit (HPU) to deliver Net Zero power.

Green Hydrogen trial

Material passports are digital documents detailing a building’s components, characteristics, and materials. They provide vital information that helps track the materials used during construction, such as specific concrete mixes, façade components, and steelwork origins. This data supports the reuse and repurposing of materials, promoting a circular economy and reducing waste and carbon emissions.

The project received an innovation credit under BREEAM for this initiative – utilised as part of the project strategy for BREEAM Outstanding. The initiative also won the ‘Delivering Sustainability with Digital Innovation’ accolade at the 2024 Digital Construction Awards.

1 Broadgate stands out as the first large-scale project to implement a digital-led material passport process.

Material Passports at 1 Broadgate

Our Three Chamberlain Square project in central Birmingham has demonstrated this by utilising a lean post-tensioned concrete structural frame and an innovative off-site prefabrication approach to the drylining works. Reducing material use, waste and emissions.

By reducing material use and reducing waste, the project is currently on track to achieve an embodied carbon result of just 479 kgCO2e/m2 (A1-A5), an exceptionally low figure for an entirely new building, along with BREEAM Outstanding and NABERS 5* accreditations.

Using less material as an industry is fundamental to reducing emissions.

Material efficiency at 3 Chamberlain Square

The approach maximises the efficiency of materials and minimises waste, with an estimated 18% less steel and 13% less concrete compared to a traditional solution. The development won the Innovation award at the 2024 BCO (British Council for Offices) Awards.

The Forge is also the first commercial building to be both constructed and operated in line with the UKGBC’s ‘Net Zero Carbon’ buildings framework. The building delivered an estimated 38% embodied carbon (A1-A5) saving compared to the project’s Stage 3 ‘BAU’ baseline. The building is also fully electric, achieving an 'A' EPC rating and is expected to achieve a 5-star NABERS UK rating once fully operational.

The Forge is the world's first major commercial building to be designed and built using the platform approach to Design for Manufacture and Assembly (P-DfMA).

Platform approach & Net Zero Carbon at The Forge

38% embodied carbon reduction

18% less steel,

13% less concrete

At our 100 Liverpool Street project, we retained approximately one third of the pre-existing structural steel frame. At 1 Broadgate, we sensitively dissembled 140 tonnes of structural steelwork from the existing asset to be re-used in another London development. Lastly, at 2 Finsbury Avenue, we identified 98 structural steel beams that could be disassembled from the existing asset and reused within the newly constructed development – saving approximately 43 tonnes of CO2e (A1-A3).

At our Broadgate framework with British Land, we have minimised our demand for new steelwork through engineering excellence.

Retained and Reclaimed Steel

Basalt comparatively reduces carbon emissions by ~60% (A1-A3) compared to steel. It is also significantly lighter and requires no hot works, improving health and safety on our sites.

We have been utilising basalt reinforcement in lieu of steel within our projects temporary works This includes basalt reinforced temporary guide walls at 2 Finsbury Avenue and temporary foundation pads at our Align JV at HS2.

Basalt Fibre Reinforcement

At a project in central London, we have been utilising a 100% Portland cement free mortar for internal masonry blockwork walls. The ‘Cemfree’ mortar provides embodied carbon savings of around ~70% (A1-A3) compared to industry leading Portland cement-based mortars. The mortar is also considered easier to clean off and remove, therefore a greater potential for blockwork to be reused when the walls are eventually demolished.

At a project in central London, we have been utilising a 100% Portland cement free mortar for internal masonry blockwork walls.

Cement Free Masonry Mortar

At our National Gallery 200 Welcome Project, we successfully coordinated the careful removal of pre-existing architectural grade glass and returned it a UK glass manufacturer for recycling into new glazing products, helping reduce emissions in the factory.

One of the barriers to lower carbon glazing products is the lack of high-quality post-consumer cullet returning to production facilities.

Glazing Recycling at The National Gallery

A newly BS 8500:2023 compliant ternary blend cement (CVI-SL) was introduced for self-compacting concrete and visual concrete mixes. This reduced the Portland cement content, whilst also reducing reliance on GGBS as a cement replacement, by incorporating limestone filler as a ternary blend. The change helped reduce embodied carbon on the project whilst improving the availability of GGBS in the market.

The Museum of London team collaborated with the supply chain to reduce the embodied carbon of concrete used on site, whilst also reducing reliance on GGBS in accordance with the latest low carbon industry guidance.

Ternary Blend Cement at The Museum of London

The new low carbon concrete has a carbon footprint following industry BSI PAS2050 calculation rules that gives a 62% reduction in CO2e per cubic metre of concrete, compared to a standard CEMI concrete, meeting the same specification in the same raw materials. The mixes trialled used up to 90% supplementary cementitious material (SCM) with an alkali activated cementitious material conforming to BS EN197.

At HS2’s Align consortium – a joint venture between Sir Robert McAlpine, Bouygues Travaux Publics, and VolkerFitzpatrick – we trialled the use of an ultra-low-carbon concrete with manufacturer Tarmac for the floor slab and parts of the walls for a pre-cast factory.

Align trial innovative low carbon concrete

The materials we exchange through the platform are assigned a digital resources passport, providing a comprehensive material identity which can be tracked and traced through the supply chain – ensuring accountability and transparency. The platform helps our projects increase the number of reclaimed materials used in our works and maximise the reuse of waste generated on our sites.

We recognise the importance of the circular economy in mitigating climate change. All our projects have access to the Excess Materials Exchange (EME) platform, this digital matching platform connects companies in the construction sector, enabling them to identify, exchange, and repurpose excess materials transforming potential waste into valuable resources.

Excess Materials Exchange

We partnered with specialist Aggreko to analyse five live tower cranes for emissions and fuel savings utilising smaller generators, BESS, and more sustainable fuels. Our projects achieved an 85% reduction in emissions across the five tower cranes with Aggreko’s BESS after rightsizing generators. That is equivalent to more than 234 tonnes of CO2 and 87,300 litres of fuel saved.

The typical nature of power consumption on construction sites means peaks and troughs are common. However, this also means generators are often oversized due to the misconception of incorporating greater power to meet start-up demand. By understanding the load profile and any patterns or timings, we can optimise the use of BESS, and integrate the best generator and BESS combination to reduce fuel costs and emissions.

Battery Energy Storage Systems (BESS)

An example being our Barkers of Kensington site in central London, through consultation our supply chain used a plethora of electric machinery such as electric telehandlers, electric mini-excavators, electric wheel dumpers, electric mini-dumpers and a number of electric robotic breakers.

Our PAS 2080 accredited carbon management system rewards our sites for utilising electric machinery instead of plant with internal combustion engines. This can reduce carbon emissions whilst also creating a healthier work environment for site operatives and reducing nuisance to our local communities.

Electric Site Machinery at Barkers of Kensington

The engineers at MDG found that the proposed solution could be significantly refined saving cost, time and materials, plus the associated embodied carbon reduced through the saved materials. The MDG optimised design reduced steel usage by over 18 tonnes and eliminated 150 metres of associated welding – this intervention saved a comparative 41tCO2e (A5).

The McAlpine Design Group (MDG) were employed by The Westbury Hotel project team to check the efficiency and efficacy of an earth retention proposal.

Optimised Temporary Works at The Westbury Hotel

Select the circles below to read the case studies.

CASE STUDIES

This spend-based approach uses Environmentally-Extended Input-Output data which align to US dollars. This highlights the importance of moving away from a spend-based approach and demonstrates the benefits that our data improvement programme will provide in 2023 and beyond.

This spend-based approach uses Environmentally-Extended Input-Output data which align to US dollars. This highlights the importance of moving away from a spend-based approach and demonstrates the benefits that our data improvement programme will provide in 2023 and beyond.